I have gone on a small poker run to gather points to qualify for some of the larger, free with qualification, tournaments of Tavern Tourneys. I was doing very well the other night when my two pair ran into a higher two pair, then two pair ran into a straight and then with three Q’s on the board and pairing the next high card my full house ran into quads. It was a wonderful night with really good players. I reached far into the higher blinds, typical, before I went all-in from late position at the final table with a Q, J suited and lost to a pair of eights.

If anyone dares suggest that I would sit on a stack to make the final table or gain points by sitting idle they are telling you a lie, spinning a yarn, telling a tale, forwarding a fib, concocting conflagrations of contortioned conflicting conveyances contrary to conscience and common sense. I play poker.

I finally finished my first poker table. It started with a couple of 4x6 particle boards that I had laying around for a long time. I actually picked them up for less than $5 a sheet some years ago to make a tree stand, but haven’t been able to fund developing our swamp land potential and holding a proper deer hunt.

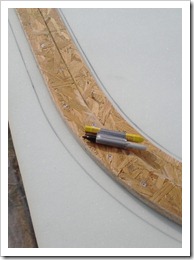

Did some sanding of the rough edges.

Went with some cheap folding legs from Harbor Freight. Really cheap, they lock in place with screws you need to take off to fold the legs down. As you may have noticed a 4x6 foot table is about as small as you can go if you are going to use folding legs.

Glued the 2lb closed cell volara foam roll, 1/8”, to the playing surface with some spray adhesive.

Trimmed it.

There’s the playing surface.

All trimmed up.

Applying the vinyl.

Our dog Ike can hardly wait till it is done.

Moving it indoors. No, you don’t need to take such obsessive care to cut the vinyl. The cuts hardly need to be straight but the spacing should be even and you don’t want to cut too close to the rail.

Make the cuts, pull taught and start stapling.

Trim away the excess. Attach the rail. You can just connect the rail with wood screws rather than the fore mentioned system I attempted to create. My system worked though it was a bit of a hassle to get everything lined up and fastened.

Ta da!